In its quest to rehabilitate itself and move beyond oil-based plastics, the plastic industry is innovating fast. This is, of course, a good thing, but in the short term is causing issues and we risk taking a backward step.

Consumers are being baffled with a variety of options and mixed messaging which risks reducing engagement in plastic reduction and increases pollution in the short term, with new bioplastics bringing with them problems of their own.

To demystify, here are the current options, in increasing order of preference:

PLA bioplastic tasting cups

Non-recyclable oil-based plastics. Eg heat resistant black polymers (ready meal trays). The bad boys in town. Persist in the environment for 100s of years. In some countries they are incinerated for energy, in others buried in landfill.

Recyclable oil-based plastics. Eg. PET, PVC. Can be recycled but are often not due to mixing of plastics within packaging (lamination) or facilities unable to process it (films). Persists in the environment and often have stabilizing chemicals to increase life.

Commercially compostable bioplastics. Products such as PLA have gained a lot of press and use as a ‘compostable’ plastic made from plant sources. This presents a big problem: added to plastic recycling they interfere with the plastics processing and added to home compost or food waste they do not break down. These plastics are designed to be used in food businesses where the food waste goes to commercial composters operating at high humidity and temperature. But this is a poor solution - food waste should go to anaerobic digesters to make gas for the grid. So a plastic which, used correctly (commercial applications), has its benefits but can cause more problems then it solves.

Oxy-biodegradeable oil-based plastics. In the short term this is a good solution. These are oil-based plastics, mostly PET, which have an additive that means they will biodegrade in the environment, BUT can still be recycled with normal PET plastics. This means that the recycling infrastructure and behaviours we currently have remain effective, and can be substituted in existing applications, but it does not persist in the environment (though occasionally some nylon is included for strength).

Biodegradeable bioplastics. The difference here is in the terminology compostable vs biodegradable. The latter will perish in the natural environment within weeks and is the best solution for single-use plastics (where they have to be used). The main application consumers will be familiar with is magazine wrapping which often uses a potato starch-based plastic. These should be discarded in household waste for incineration. A bad use case is food waste bags for food waste collections - the food waste goes to make gas in anaerobic digesters and the bags have to be removed. Better to not use them.

Our plastics strategy

As with all consumption, the reduce, reuse, recycle mantra applies to plastics, but be aware that there are different plastics aimed at commercial and residential applications.

What do we do to mitigate our impact?

We have never used, or have removed most plastic from our operations. We don’t buy anything which has mixed materials with recyclable plastics like shipping envelopes with bubble wrap laminated to card, and don’t use ‘luxury’ packaging or bags where films have been laminated to card to give a texture.

We have two bioplastic sources in the distillery at present:

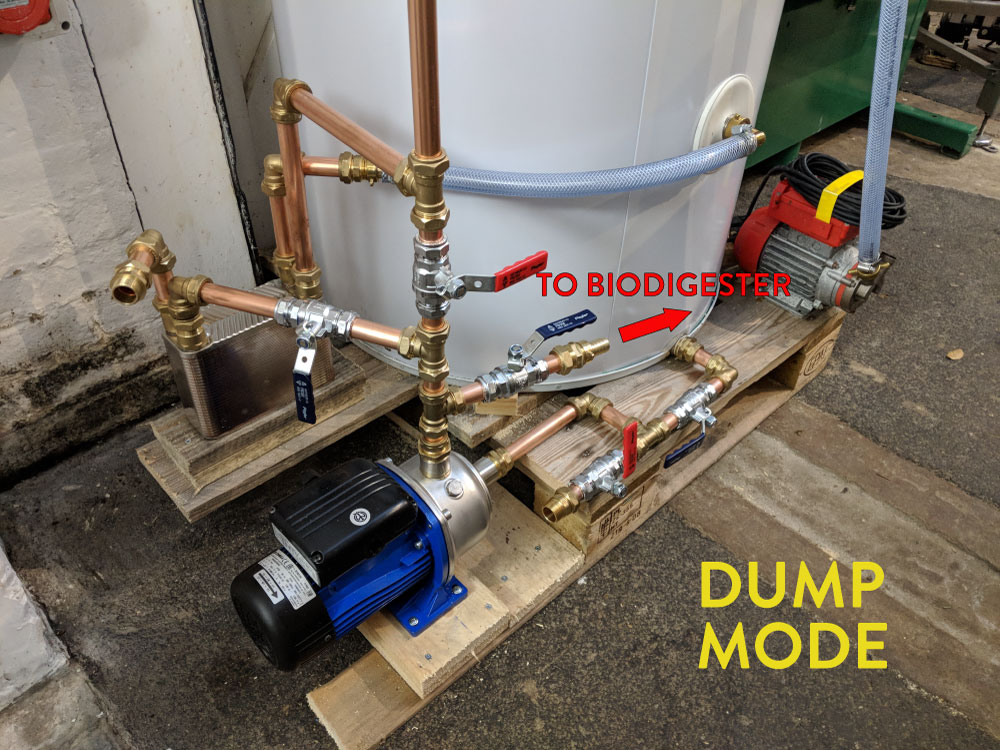

Our high temperature composter to break down PLA bioplastic in tasting cups.

PLA tasting cups. The standard in the industry at consumer shows and events are PVC tasting cups and as an industry we go through thousands. Being at many of these events we can say that they are never collected and recycled. PLA subsitutes are somewhat better and we try and make sure we collect and return them to the distillery to feed to our hot composter!

ePET inflatable shipping bags. Most of our shipments are in card only packing. Sometimes we need to ship in robust inflatable shipping pouches. We use an oxy-biodegradeable pack and try to make it clear to our customers to recycle these.

The future of plastics

Plastic is a great material. As a vessel, container, pipe or seal, it is perfect for its application and highly durable. Precisely why it is bad for single-use applications.

Even compostable plant-based bioplastics will be regulated alongside oil-based plastics in the short term due to their compromises. The future of single-use plastic is plant-based and fully biodegradable.

Until then its going to take a bit of engagement and consideration from us all.